How ventilators work

April 5, 2020

COVID-19: What Infrared Thermometers are Used for

April 13, 2020Types of Eye and Face Protection

Selecting the most suitable eye and face protection should take into consideration the following elements:

- Ability to protect against specific workplace hazards

- Should fit properly and be reasonably comfortable to wear

- Should provide unrestricted vision and movement

- Should be durable and cleanable

- Should allow unrestricted functioning of any other required PPE

Some of the most common types of eye and face protection include:

Safety Glasses

Safety glasses have safety frames constructed of metal or plastic and impact-resistant lenses. Side protection is required.

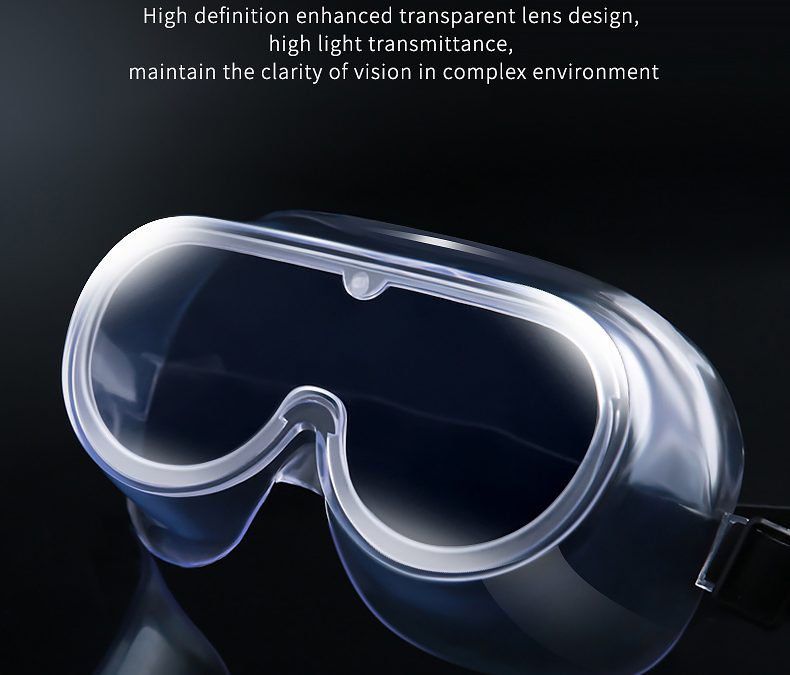

Chemical Splash Goggles

Tight fitting eye protection that completely covers the eyes, eye sockets and facial area surrounding the eyes. Provides protection from impact, dust and splashes.

Dust Goggles

Dust goggles, sometimes called direct ventilated goggles, are tight fitting eye protection designed to resist the passage of large particles into the goggles.

Fluid Resistant Shields

These shields are fluid resistant or impervious and provide splash protection from biological material, such as human or non-human primate body fluids.

These shields do not provide protection against chemicals or impact hazards and do not comply with ANSI Z87.1

Face Shields

These shields extend from the eyebrows to below the chin and across the width of the employee’s head. Face shields protect against potential splashes or sprays of hazardous liquids. When worn for protection against UV, must be specifically designed to protect the face and eyes from hazardous radiation.

Laser Eyewear

Protective eyewear is required for Class 3 and 4 laser use where irradiation of the eye is possible. Such eyewear should be used only at the wavelength and energy/power for which it is intended.

Welding Shields

Constructed of vulcanized fiber or fiberglass and fitted with a filtered lens, welding shields protect eyes from burns caused by infrared or intense radiant light; they also protect both the eyes and the face from flying sparks, metal splatter and slag chips produced during welding, brazing, soldering and cutting operations